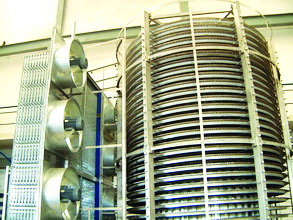

INDIVIDUAL QUICK FREEZER (IQF)

In Today's world, food preservation is more important than ever before, Historically there were many Methods of food preservation, like drying, smoking, pickling, salting etc.. These rather primitive methods are still widely used today, not only in backward societies, where no other means are available, but also in modern societies where they serve to supplement the more modern methods of food preservation like refrigeration.

In the Individual Quick Freezing (IQF) process, unlike other freezing processes, the products are frozen as individual pieces. This offers greater convenience to the consumers and hence adds more value to the product. The IQF process is far superior to the conventional processes. In Quick freezing, small ice crystals forms within the product thus its own fresh quality is maintained even after extended shelf life. Most foods can be preserved for a long time if they are frozen quickly and kept at a low temperature until ready for use. Slow, natural freezing destroys food because the low temperatures draw all the water from the tiny cells of the food, affecting color and flavor.

Quick freezing method prevents breakage of the cell walls as the freezing process is so quick. Thus, in quick-frozen food most of the flavor, color and firmness are retained.

Application of Individual Quick freezing (IQF):

• Fruit & vegetables processing

• Meat & fish Processing

• Ready to eat products

• Other Cooked Food items

Features:

IQF freezer unit along with matching refrigeration packages,[ liquid over feed type ] all are ready to install at the site.

• Modules of capacity ranging from 250 to 3000 kg/hr.

• Enclosure made of energy efficient sandwich panels with RPUF core and stainless steel /per-painted GI metal lamination inside and outside respectively.

• Stainless steel finish floor with built in drain system.

• Single or multiple belt unit of SS/ PE / POE.

• High static fans for excellent fluidization.

• Unique thumbing system to disburse product lumping.

• Variable speed drive with motor control VFD

• Varying fin type Cooling coil of SS tubes/aluminum fins suitable for ammonia liquid pumping.

• PLC based control panel with Touch screen and product based operation modes.

• Automatic Air defrost system [for Straight line IQF] with unique FROST BUSTER.

Technical Description:

IQF freezer is completely pre-fabricated, factory tested prior to shipping. The conveyor made of continuous belt, MOC SS / PE / POE. The conveyor supports are made of Aluminum lined, low friction, food grade, plastic wear strips [UHMPV] designed for minimum belt wear. The enclosure of the chamber is constructed with rigid polyurethane insulation, of 150mm thick Wall & ceiling, 200mm thick for floor along with entry/inspection doors, walk ways with in the chamber along with stairs, located at critical locations for easy inspection, cleaning, and maintenance. The freezer is built to food grade standards.

Cooling coil will be of SS/Al construction with varying fin configuration for enhanced performances. The frigid air is delivered by high-efficiency aero-foil construction fan impeller which is directly driven by high efficiency motors. Both Straight and spiral units are equipped with water defrosting arrangement for coil. The straight line IQFs will have an automatic, advance Air Defrost technology [ADF] system for a longer operation period, between defrost intervals. The floor shall be of SS Finish with built in Clean Flow drainage systems. In feed conveyor is covered with insulated boxing & outlet feed with product collection tray. The straight line IQF units will have an infeed shaker unit at the product entry point.